Mountainside construction provides exciting challenges for an engineer/builder who enjoys them

By Scott Webb

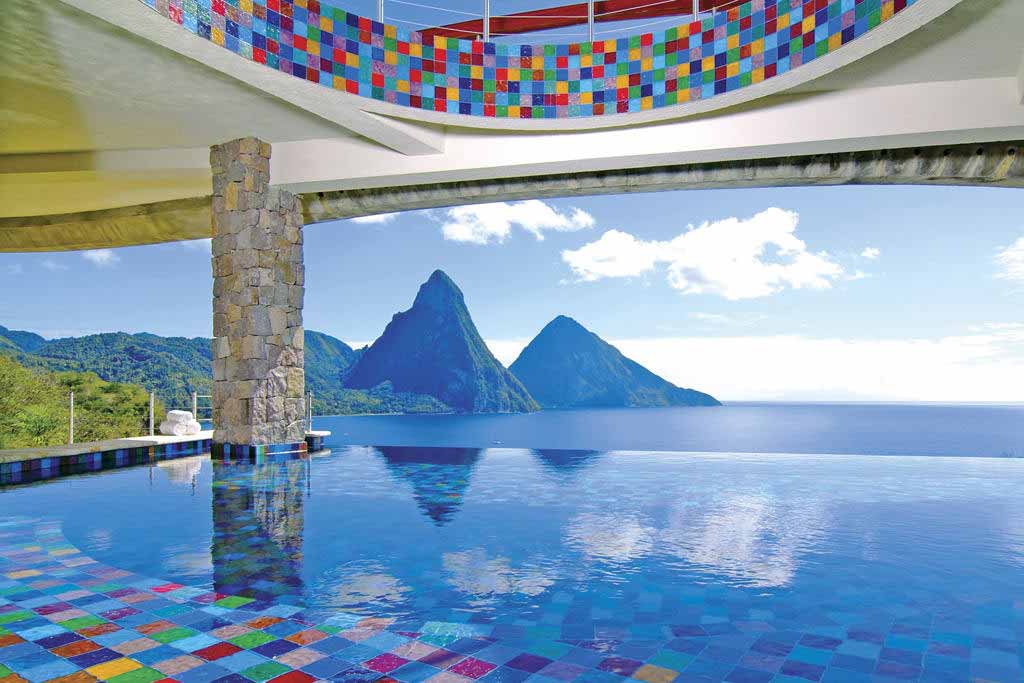

A sweet pool with three knife-edges and a fourth vanishing edge overlooking the Blue Ridge mountains of North Carolina provides ample builder interest on its own. But hang that vessel off a granite cliff, with all the complexities of cantilever construction and load support, and you have the kind of project that stimulates an aquatic engineer.

Such was the joyful challenge for builder Mark Dorsey, licensed engineer, GENESIS instructor and president of Medallion Pools, Asheville, N.C.

“When we arrived on the scene, the homeowner had actually been hammering away on the granite rock cliffside for about a year, trying to get ready for construction. They almost gave up on the property, they’d spent so much on it. They kind of got into it with no way of getting out of it, other than just plowing ahead and finishing.

The problem was that they couldn’t do traditional blasting. So there was nothing else to do but a whole lot of hydraulic hammering.”

The goal was worthwhile — a home with a spectacular view of Asheville, the French Broad River valley and the mountains above, complete with a pool to reflect the entire scene — but there were some construction quandaries to be solved. All told, it took 2 1/2 years, a year to hammer out a flat place to stand and build on, and another 1 1/2 years to complete construction.

“Basically, in a situation like this, you can’t get your equipment below the site, so you have to do everything from above.”

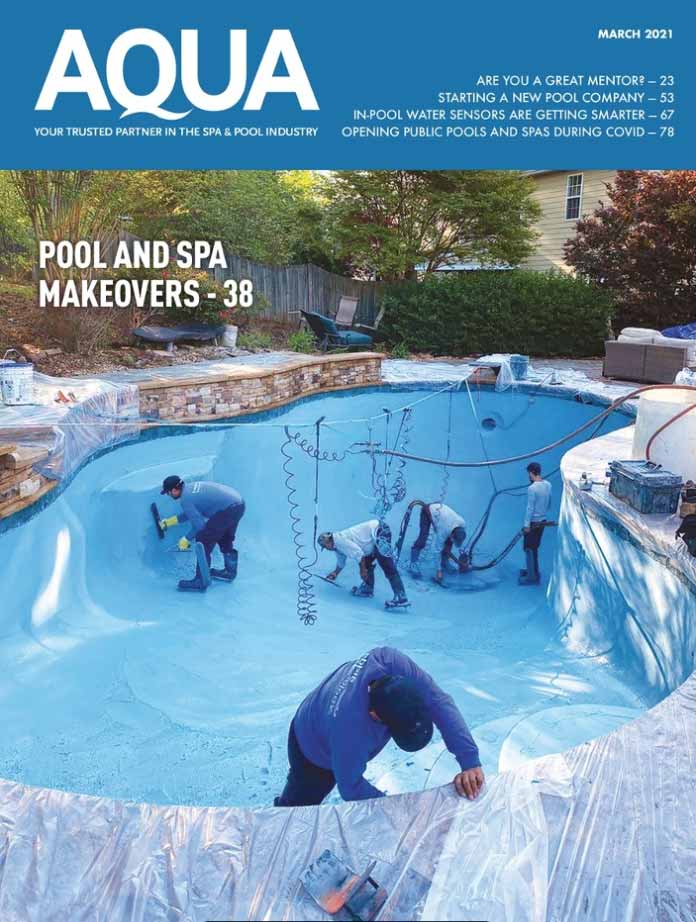

CANTILEVER CALCULUS

With a stout retaining wall anchored into the mountain and extending from the house across the face of the pool area, notched for the cantilevered pool and spa, Medallion’s engineering team got to work on the torsion calculations. “The spa extended 5 feet out beyond the retaining wall, and the pool extended 3 feet out,” says Dorsey. “The most challenging part of it was the forming for the concrete cantilever supports. When we shot the cantilever forms, we’re supporting wet concrete with wood (see picture of wood support structure), and those calculations were important, too. We checked those several times to make sure we had it right.”

“There were several ways of doing it, and it wasn’t like you could get a piece of equipment below the wall. We had to do everything from above. So we basically built heavy duty framing, like you would frame a deck with 2-by-12s, and then we hung that over the edge. And lag-bolted it to the top of the wall, and then supported that down to the footing at an angle with 4-by-4s.”

A DISCREET SURGE TANK

Another unusual facet of the project was the overflow system Medallion Pools uses.

“We don’t build the trough below the vanishing edge big enough for the entire surge capacity,” says Dorsey.

“We use a gravity system where the overflow drains down into a 1,300-gallon plastic tank in the equipment room underneath the porch, and then gets circulated back into the pool.”

The stainless steel overflow trough is 8 inches deep by 8 inches wide with pipe outlets positioned every 4 feet to ensure complete drainage.

“We have a local steel fabricator make the trough for us, which saves a lot of money and time, as we can hang it in just one day with the use of special tabs and bracing, instead of shooting a surge trough as another concrete piece on the outside of the pool. This system also results in less evaporation and heat loss.”

With the cantilever support structures and the overflow drainage system in place, and the pool and spa shot, it was time for a finish worthy of the stylish mountain retreat.

“The choice of finish on the pool is always a difficult one for a homeowner,” says Dorsey, “but when I showed her the Pebble Tec Lightstream iridescent tiles, she got excited about having those on the spa. Eventually she went with the Pebble Brilliance finish in the Majestic Sound color for the pool — those have been so reliable for me over the years, and we’ve found they make chemical start-up and maintenance easier, requiring little to no brushing.”

With finishes applied and the pool filled, Dorsey had a chance to step back and reflect on the pleasures of meeting a difficult challenge and fulfilling the dreams of a client. Especially enjoyable was the experience of making detailed plans, force diagrams and calculations, the accuracy of which was borne out in the final product.

“I’m an engineer, and I have another structural engineer on staff. Together, we enjoy the technical part of the job,” Dorsey says. “It’s a lot of fun. It’s so fulfilling to put something on paper and then go out there and actually do it.”